Mower Magneto Coil Reads Correct Ohms but No Spark

How to examination and repair small-scale engine ignition organization issues?

Is there no spark in the engine of your lawn mower, snow blower or outdoor ability equipment? Follow this guide to examination your ignition system - including curlicue, switch & module - to identify any bug and troubleshoot repairs.

If y'all know your specific problem, jump downward to the section for stride-by-step instructions.

How Do Ignition Systems Work in Small-scale Engines & Lawn Mowers?

Servicing Spark Plug Problems

How to Test the Ignition Coil in Your Small Engine

Testing & Replacing a Finish Switch

Ignition Module Failure

How To Inspect the Flywheel & Key

![]() WARNING: Ever read the engine and equipment manual(southward) earlier starting, operating, or servicing your engine or equipment to avoid personal injury or belongings damage. Run into an authorized dealer or contact Briggs & Stratton if you are unsure of any procedure or have additional questions. Find all Engine Safety Warnings

WARNING: Ever read the engine and equipment manual(southward) earlier starting, operating, or servicing your engine or equipment to avoid personal injury or belongings damage. Run into an authorized dealer or contact Briggs & Stratton if you are unsure of any procedure or have additional questions. Find all Engine Safety Warnings

How Practise Ignition Systems Work in Modest Engines & Lawn Mowers?

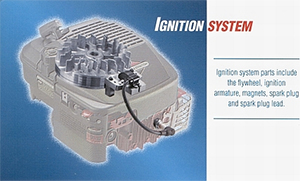

The ignition system is the starting arrangement for your pocket-sized engine. Whether you get-go the engine with a pull rope or the plow of a key on an electric beginning motor, you're relying on the ignition system to produce a spark inside the combustion chamber.

Small Engine Ignition Parts

- Flywheel with magnets

- Coil or Armature

- Push starting or Pull Cords (depending on your engine blazon)

- Spark Plug Lead

- Spark Plugs

When you lot starting time your lawn mower or small engine, you turn the flywheel and its magnets pass the coil (or armature). This creates a spark. The ignition arrangement coordinates the timing so that the spark will ignite the air-fuel mixture in the combustion sleeping room only equally information technology reaches maximum compression in each engine bike- thus, maximizing the engine's power.

In one case the engine is running, the flywheel keeps rotating, the magnets continue passing the ringlet and the spark plug keep firing based on a specific timing.

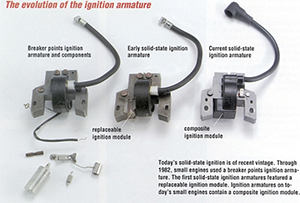

Types of Ignition Systems

- Solid-country systems: the more than modernistic option, these systems utilise a tiny transistor in the coil or armature to close the electrical circuit that travels through the spark plug atomic number 82 to the spark plug(due south).

- Breaker bespeak systems: used on engines made before 1980, these systems use a mechanical switch instead of a transistor to close the electrical circuit used to produce a spark.

Common Flywheel Problems

If you are experiencing ignition timing issues, this is nigh oft due to a sheared flywheel key. You can also exam the flywheel magnets for any potential issues.

For information regarding this, please visit our Inspecting the Flywheel and Key FAQ.

Common Spark Plug Problems

- The required spark plug gap and voltage can vary depending on temperature, altitude and your engine settings.

- Sometime, damaged or fouled spark plugs can also require service or replacement

How To Test the Ignition Whorl in Your Pocket-sized Engine

![]() Rubber Warnings:

Rubber Warnings:

Stay clear of any rotating, moving parts, or other hazardous areas whenever attempting to get-go the engine or equipment.

The curl is probably the easiest thing to check and therefore the first matter to bank check when embarking upon ignition organisation troubleshooting.

Testing the Gyre or Armature

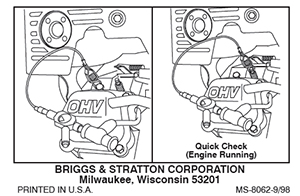

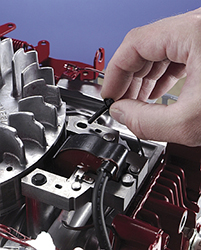

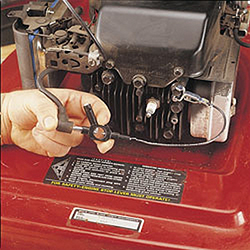

- Step 1: Clip i stop of the spark tester (service part number 19368) to the ignition cablevision and the other grounded to the cylinder head as shown below.

- Step two: Spin the flywheel rapidly (at least 350 RPM) and watch for spark in the tester window.

If the spark jumps the tester gap, your ignition gyre is working fine. If non, it needs to be replaced.

Engine quits while running? Hook the tester upwards betwixt the ignition cable and the spark plug and offset the engine. When it stops, monitor the window.

Mutual Mistakes When Testing Coils

- Be sure to unhook the roll from the equipment wiring harness too every bit the engine's wiring harness and use the spark tester. Many a technician is fooled into replacing a practiced ringlet considering the coil grounding lead was shorting out confronting a piece of sheet metallic.

- Do NOT attach the tester to the spark plug for this exam. The engine may start. Without the grounding pb installed, you won't be able to turn it off.

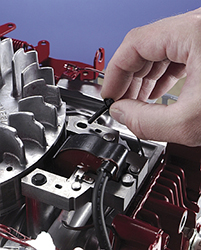

Replacing Ignition Coils or Armatures

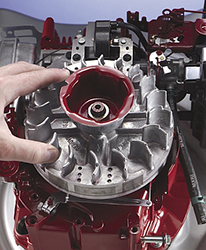

An ignition armature must be set at a precise distance from the flywheel. Your engine repair transmission volition provide the proper gap for your engine. Mutual armature gap ranges are .006 - .010" and .010 - .014". Armatures are ofttimes packaged with a shim to assist in setting the gap. Alphabetize cards of the proper thickness also work well.

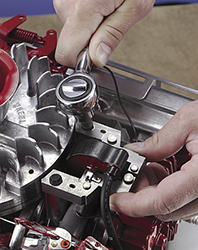

- Unhook the spark plug wire and secure information technology, removing whatsoever batteries, if equipped.

- Remove the one-time ignition coil (armature) mounting screws.

- Then, disconnect the stop switch wire from the flywheel brake and remove the coil.

- Attach a replacement scroll from the original engine manufacturer, using mounting screws.

- Then, push button the coil (armature) away from the flywheel and tighten one spiral.

- Plow the flywheel and so the magnets are on the reverse side from the ignition coil (armature).

- Place the appropriate shim betwixt the rim of the flywheel and the ignition armature. While belongings the shim, plow the flywheel until the magnets are directly adjacent to the armature

- Loosen the tight screw so the magnets pull the ignition armature confronting the flywheel and shim. Then, tighten both mounting screws and rotate the flywheel until the shim slips gratuitous.

- Reconnect the finish switch.

Have an older, billow point ignition system?

Breaker point ignition systems were mutual through 1982. You lot can improve its reliability on a single-cylinder Briggs & Stratton engine equipped with breaker points and a two-leg armature by installing a solid-state ignition conversion kit (service office number 394970) that bypasses the points (conversion kit will not piece of work with a 3-legged ignition armature).

Additional questions? Delight consult a Briggs & Stratton Service Dealer for conversion kit and installation.

Testing & Replacing a Terminate Switch

![]() Safety Warning: Stay clear of any rotating, moving parts, or other hazardous areas whenever attempting to start the engine or equipment.

Safety Warning: Stay clear of any rotating, moving parts, or other hazardous areas whenever attempting to start the engine or equipment.

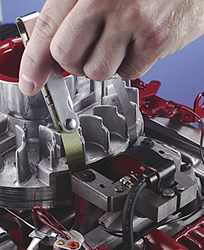

- Step 1: Insert the spark plug pb on one end of a spark tester and attach the tester's alligator clip to footing, such every bit an engine bolt (see paradigm below).

- Step 2: Place the equipment stop switch control in the OFF or STOP position. If the engine is not connected to the equipment, ground the stop switch wire to the cylinder.

- Footstep 3: Attempt to offset the engine using the rewind cord or key (if equipped).

In that location should be no spark. If a spark appears, audit the stop switch for damage. Consult your authorized service dealer if you lot observe a faulty switch. - Step 4: Place the stop switch control in RUN or START position.

If the engine is not connected to the equipment, make sure the cease switch wire is not grounded. - Step 5: Try to get-go the engine.

A spark should be visible in the tester. If no spark appears, check for broken wires, shorts, grounds or a defective stop switch.

Once you lot take confirmed that the end switch is working, reconnect the spark plug lead.

If your ignition start or push button push kickoff needs replacing, consult a Briggs & Stratton dealer virtually you.

Ignition Module Failure

Because the ignition module is electronic and does not utilize moving components, it is normally one of the most reliable part of the engine. When it does fail, information technology is normally due to oestrus caused from improper wiring of the ground wire to battery voltage.

If the engine does non produce spark, other areas of the ignition organization should be checked before focusing on the ignition module equally source of failure (see in a higher place).

If no error is discovered in the above mentioned areas, the ignition module itself may demand to be examined. To all-time determine the cause of failure, please consult an Authorized Dealer.

Mower Magneto Coil Reads Correct Ohms but No Spark

Source: https://www.briggsandstratton.com/eu/en_gb/support/faqs/browse/ignition-system-theory-and-testing.html

0 Response to "Mower Magneto Coil Reads Correct Ohms but No Spark"

Post a Comment